CNC Wire erosion

PACT Engineering have invested in CNC Wire Erosion technology to enhance its capability in producing complex and intricate components to a very high level of precision for a diverse customer base.

Why choose PACT Engineering?

Our range of machines allows us to program multiple components with a variety of complex apertures using the automatic in process threading cycle.

Our skilled engineers can deliver projects with speed and precision, ensuring a high level of customer satisfaction.

Wire eroding can be used for Gear Cutting , Keyways and Splines as a cost-effective alternative to traditional machining methods. Wire eroding can also be used to produce tapers, 4 axis profiles, square holes and splitting components where a minimal gap distance is required. It can also be ideal for producing Press and form Tools with tight dimensional requirements.

Wire eroding can achieve extremely high levels of precision with tolerance as tight as +/- 0.002mm (0.00008inches) this is ideal for producing complex parts. It can cut through materials that are very hard and difficult to machine using conventional methods ,including hardened steels, exotic alloys and heat-treated material.

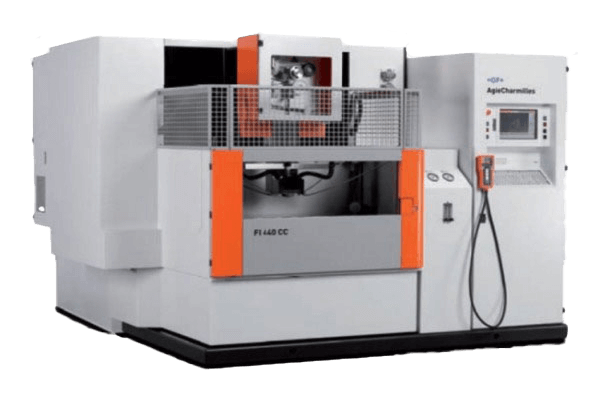

Agie Charmilles Robofil 440 CC

Plant list

WIRE ERODING – EDM

Charmilles Wire Eroder 440CC – Max capacity 550mm X 350mm X 400mm

Charmilles Wire Eroder 240CC – Max capacity 350mm X 250mm X 200mm

Charmilles Die Sinking 2-LC – Max height can easily be adapted

How can we help?

When you require high-precision components, our dedicated team is committed to delivering exceptional service.

Contact us today to learn more about our services and how we can help your business.